Frequently Asked Questions (FAQs)

This section addresses common questions about the Automatic Can Sealing Machine, particularly for small to medium-sized food and beverage businesses. If you have a question not covered here, please don't hesitate to contact our dedicated support team.

1. General Operation & Setup

Q: Is the Automatic Can Sealing Machine easy to set up and operate? A: Yes, absolutely! The machine is designed for intuitive, one-touch automatic operation. Setup involves minimal effort, typically just plugging it in and positioning your cans. A detailed user manual and quick-start guide are provided to get you sealing quickly.

Q: What kind of training or support is available after purchase? A: We offer comprehensive support to ensure you get the most out of your machine. This includes access to our online troubleshooting guides, FAQs, and dedicated Australian-based customer support for any technical assistance or operational queries.

Q: What are the dimensions and weight of the machine? Is it suitable for a small commercial space? A: The machine features a compact benchtop design, making it ideal for small commercial kitchens, cafes, breweries, and pop-up setups. Please refer to our "Technical Specifications" tab/page for precise dimensions 600mm (height) x 200mm (width) x 400mm (depth) and approx. 7kg weight, which is designed for efficient use of space.

2. Can & Lid Compatibility

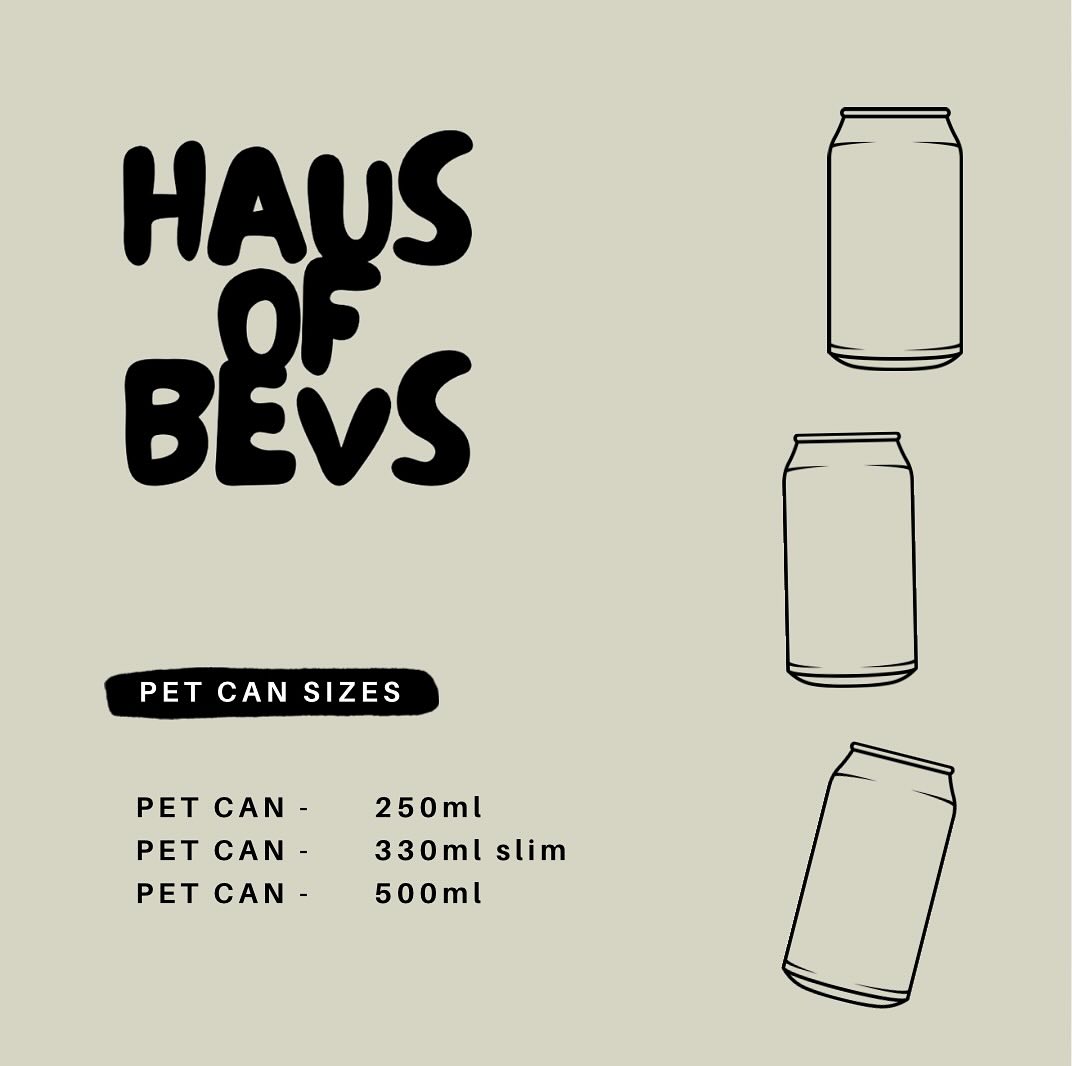

Q: What types and sizes of cans does the machine seal? A: The machine is specifically designed to seal standard aluminum and PET (plastic) cans.

Q: Does the machine come with cans and lids? Where can I purchase compatible supplies? A: The Automatic Can Sealing Machine is sold separately from cans and lids. Please see our products listing for all the different options in PET cans and lids.

Q: Can I use different types of lids, like pop-top beverage lids, with this machine? A: Yes, while it's specifically designed for easy-open, peel-off aluminum foil lids, it can also effectively seal standard beverage pop-top lids of compatible sizes. Please see our product pages for more information.

3. Performance & Output

Q: What is the sealing capacity of the machine? How many cans can it seal per hour? A: The machine offers impressive efficiency, this high capacity is perfect for streamlining your production and handling increased demand.

Q: How consistent are the seals? Will my products be secure and fresh? A: Absolutely. Our machine is precision-engineered to create uniform, hermetic (air-tight and liquid-tight) double seams every time. This ensures maximum freshness preservation, minimizes spoilage, and provides a professional, leak-proof finish for your products. Keeps your servings fresh for up to four days.

Q: Is the machine noisy during operation? A: The machine operates quietly, with a noise to ensure it won't significantly disrupt your commercial environment.

4. Food & Beverage Specific Applications

Q: Can I really put desserts and appetisers inside cans? How does the peel-off lid work for this? A: Yes! This is a revolutionary feature. The machine is compatible with special peel-off lids, allowing you to "plate" desserts, appetizers, and snacks directly inside the cans. When opened, the entire top peels off cleanly, providing a unique and hygienic single-serve presentation that delights customers.

Q: Is the machine suitable for sealing carbonated beverages like craft beer or cocktails? A: Yes, it is perfectly suited for carbonated beverages. The precision sealing mechanism ensures that carbonation is effectively preserved, keeping your craft beers, cocktails, and sparkling drinks fresh and fizzy, just as you intended.

Q: Can I use this for hot-fill or cold-fill products? A: The machine is able to seal hot beverages, but unfortunately the PET cans and lids are not suitable more that 60 degrees Celsius or 140 Fahrenheit.

5. Maintenance & Support

Q: How do I clean and maintain the Automatic Can Sealing Machine? A: The machine features an easy-access design for simple and hygienic cleaning. Regular wiping down of surfaces and periodic checks of moving parts as outlined in the user manual will ensure optimal performance and longevity.

Q: What is the warranty period for the machine? A: The Automatic Can Sealing Machine comes with a 1-Year Manufacturer's Warranty, covering parts and defects. This ensures peace of mind for your business investment.

Q: Where can I get support if I encounter an issue? A: We provide dedicated 24/7 customer support. You can reach us via hello@hausofbevs.com during business hours, or access our online resources for troubleshooting.

6. Business Value & ROI

Q: How can this machine help my small F&B business grow? A: This machine offers multiple growth opportunities:

- Increased Efficiency: Automate packaging, reduce labor costs, and free up staff for other tasks.

- New Product Lines: Easily introduce trendy canned desserts, appetizers, craft beverages, and more, expanding your menu.

- Enhanced Brand Image: Professional, sleek packaging elevates your brand and attracts new customers.

- Extended Shelf Life: Preserve freshness, reduce waste, and allow for wider distribution.

- Unique Selling Proposition: Stand out in a crowded market with innovative packaging and serving concepts.

Q: Is this a good investment for a startup or micro-business? A: Absolutely. While it's a professional-grade machine, its compact size and ease of use make it an ideal initial investment for startups and micro-businesses looking to scale efficiently, professionalize their product presentation, and differentiate themselves without requiring large-scale industrial equipment. The time and labor savings alone can offer a significant return on investment.

For any further specific business inquiries or to discuss bulk solutions, please do not hesitate to contact our sales team directly at hello@hausofbevs.com!

Technical Specifications

General Machine Specifications

Model: Automatic Can Sealing Machine

Primary Application: Sealing of aluminum and PET cans for a wide range of food and beverage products including carbonated drinks, cocktails, craft beers, juices, smoothies, desserts, appetizers, and snacks.

Sealing Mechanism: Automatic rotating head with stationary can base.

Operation: One-touch automatic sealing cycle.

Dimensions (L x W x H): 600mm (height) x 200mm (width) x 400mm (depth)

Weight: Approx. 7kg

Housing Material: Durable painted steel / high-grade alloy

Sealing Components Material: Food-grade stainless steel for contact parts, hardened alloys for mechanical components.

Colour: Black and White

Mounting: Benchtop / Freestanding

Electrical & Power Requirements

Voltage: 240V AC

Frequency: 50Hz

Power: 370W

Plug Type: AUS, UK, USD, EU standard plug types

Energy Efficiency: Designed for optimal power consumption in continuous operation.

Performance & Output

Sealing Time per Can: Approximately 3 seconds

Seal Type: Hermetic (air-tight and liquid-tight) double seam.

Consistency: Precision engineered to ensure uniform and secure seals, minimizing spoilage and leakage.

Can & Lid Compatibility

Can Sizes Supported:

- 210ml

- 250ml

- 330ml

- 500ml

- 650ml

Can Materials: Aluminum and PET (Polyethylene Terephthalate) cans.

Lid/End Type: Compatible with standard traditional lid, and easy peel style lid.

Lid Style: Specifically designed for easy-open, peel-off aluminum foil lids with a pull tab (for food applications). Can also accommodate standard beverage lids.

Safety & Operation

Safety Features: Integrated safety mechanisms to prevent operation errors and ensure operator protection.

Controls: Intuitive, user-friendly control panel with clear indicators.

Operational Environment: Recommended for indoor use in dry, stable conditions.

Maintenance & Support

Cleaning: Easy-access design for simple and hygienic cleaning procedures.

Durability: Built for continuous commercial operation with robust components.

Warranty: 1-Year Manufacturer's Warranty covering parts and defects.

Support: Dedicated Australian-based customer support and technical assistance.

Resources: Access to online troubleshooting guides and FAQs.

Quick Start Guide

This Quick Start Guide provides a concise overview to get your Automatic Can Sealing Machine up and running swiftly. For detailed information, please refer to our full Technical Specifications and FAQs pages.

Step 1: Unboxing & Placement

- Carefully unbox your Automatic Can Sealing Machine.

- Place the machine on a stable, flat benchtop surface in your desired commercial space (kitchen, brewery, cafe, pop-up setup). Its compact design ensures efficient use of space.

- Ensure the machine is located near a standard 240V, 50Hz power outlet.

Step 2: Power Connection

- Plug the machine's power cord into a compatible 240V AC power outlet.

- Turn on the machine using its power switch (refer to your user manual for exact location if needed).

Step 3: Can & Lid Preparation

- Ensure you are using standard aluminum or PET cans. These are sold separately.

- Use compatible series can ends (lids). These are sold separately.

- Fill your cans with your desired food or beverage product (desserts, appetizers, snacks, craft beers, cocktails, smoothies, etc.), leaving appropriate headspace as per your product's requirements.

- Carefully place the compatible lid onto the filled can.

Step 4: Automatic Sealing Process

- Place the lidded can onto the machine's designated sealing platform.

- Initiate the one-touch automatic operation (e.g., press the start button).

- The machine's innovative rotating head will engage and seal the can without the can itself moving, ensuring precise and spill-free operation.

- Allow the automatic cycle to complete. The machine will typically indicate when the seal is finished.

- Remove the perfectly sealed can from the platform.

Step 5: Post-Sealing (Quality & Freshness)

- Your can is now hermetically sealed, ensuring maximum freshness and carbonation preservation for your food and beverage products.

- Enjoy the professional, leak-proof finish that elevates your product presentation.

Quick Maintenance Tip:

The machine features an easy-access design for simple and hygienic cleaning. Wipe down surfaces regularly to maintain optimal performance.

Cleaning & Maintenance of the Sealing Process

Regular cleaning and simple maintenance are key to ensuring optimal performance, consistent sealing, and longevity of your machine.

Daily Cleaning (After Each Use):

- Disconnect the machine from the power supply.

- Wipe down all exterior surfaces with a damp, clean cloth.

- Clean the sealing platform and surrounding areas, removing any spills, debris, or product residue. Use a mild, food-safe cleaner if necessary, ensuring no liquid enters internal components.

- Ensure the rotating head and can base are free from stickiness or buildup.

Sealing Surface Inspection:

- Periodically inspect the sealing rollers and chuck (the part that presses down on the lid) for any signs of wear, damage, or accumulation of product.

- Ensure these components are clean and smooth to guarantee a consistent, high-quality seal. Refer to your user manual for detailed inspection points.

Troubleshooting & Basic Maintenance

This section covers common minor issues and maintenance tips. For complex problems, always refer to your full user manual or contact support.

Seal Quality Issues (e.g., inconsistent seals, leaks):

- Check Can & Lid Compatibility: Ensure you are using the correct aluminum/PET cans and series lids.

- Proper Can Placement: Verify the can is correctly seated on the platform before initiating the seal.

- Cleanliness: Residue on sealing surfaces can affect seal quality. Perform a thorough cleaning as per the "Daily Cleaning" guide above.

- Headspace: Ensure appropriate headspace in the can. Overfilling or underfilling can impact the seal.

- Regular Inspection: Check the sealing rollers and chuck for any visible wear or damage.

Machine Not Powering On:

- Verify the power cord is securely plugged into both the machine and a live power outlet.

- Check the power switch on the machine.

General Maintenance:

- Keep the machine in a dry, stable environment.

- Avoid using abrasive cleaners or materials that could damage surfaces.

- Refer to the full user manual for any specific lubrication or periodic maintenance requirements.

Need More Help?

Refer to your full user manual for detailed instructions and troubleshooting.

Visit our FAQs page for answers to common questions.

For technical assistance or specific business inquiries, contact our dedicated customer support at hello@hausofbevs.com.